...and a 2500-rpm stall speed converter would be even quicker, since

the engine could be held against the brake, preloading the converter,

to build usable boost pressure before leaving the starting line.

Other possibilities include running with open exhaust, bypassing the

catalytic converter and mufflers for |

|

off-road use and substituting

premium fuel. In this mode of operation, the system will produce 9-11

pounds of boost. And if that isn't enough, H-O also has a twin

turbo kit that will similarly fit under the stock hood [never produced].

Other options, such as a waste gate and a compressor mounted water

injection system are also available for all-out |

|

applications. Additionally

for the do-it-yourselfer, the pressure bonnet and Q-Jet modification

pieces, the waste gate, the water injection system, the Rajay turbos,

and most other kit components can be purchased separately, thus simplifying

"blow thru" installations on any vehicle.

Study the accompanying photos and application list. You may find just

what you need to "transform" your machine into a force-fed muscle car.

|

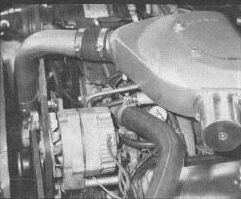

All lines have been routed to clear all existing belts and

accessories, including air conditioning.

All lines have been routed to clear all existing belts and

accessories, including air conditioning.

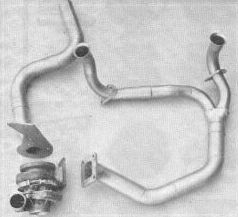

The heart of the system is the exhaust plumbing and

the compact Rajay 301E turbocharger. Note the small hole

atop the compressor inlet for attachment of the optional

water injection.

The heart of the system is the exhaust plumbing and

the compact Rajay 301E turbocharger. Note the small hole

atop the compressor inlet for attachment of the optional

water injection.

Greatly simplifying the installation, is this modified

front engine cover. It includes the turbo oil drain provision

and a relocated lower radiator hose outlet. Also included is a

special lower radiator hose and the turbo oil supply and

return lines.

Greatly simplifying the installation, is this modified

front engine cover. It includes the turbo oil drain provision

and a relocated lower radiator hose outlet. Also included is a

special lower radiator hose and the turbo oil supply and

return lines.

To provide clearance for the turbo exhaust, the

right side of the engine is raised slightly with a special

motor mount. Raising the engine creates an access problem

with the left valve cover, so a modified valve cover

is provided to clear the power brake.

To provide clearance for the turbo exhaust, the

right side of the engine is raised slightly with a special

motor mount. Raising the engine creates an access problem

with the left valve cover, so a modified valve cover

is provided to clear the power brake.

On "blow through" installations, fuel pressure must be

higher that boost pressure. This modified fuel pump is

connected via a pressure line to the carb float bowl to

reference pump pressure above boost pressure. The preformed

steel fuel line is also supplied.

On "blow through" installations, fuel pressure must be

higher that boost pressure. This modified fuel pump is

connected via a pressure line to the carb float bowl to

reference pump pressure above boost pressure. The preformed

steel fuel line is also supplied.

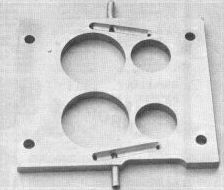

This plate is installed beneath the carb to

pressurize the modified throttle shaft bosses with dry air,

thus preventing a possible leak of fuel-contaminated air into

the engine compartment.

This plate is installed beneath the carb to

pressurize the modified throttle shaft bosses with dry air,

thus preventing a possible leak of fuel-contaminated air into

the engine compartment.