|

|

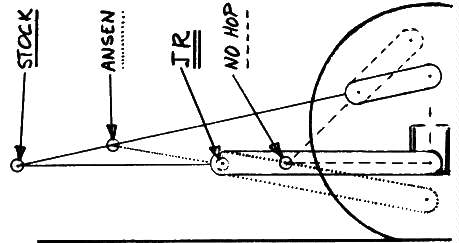

This month's topic will discuss how to set up a drag racing link-coil

rear suspension for 1964-75 "A", "B" and

"G" body Pontiacs.

The

"upsetting" forces due to engine and driveshaft torque are the same

as described last month, but chassis lift force (also downward force on the tires)

is provided by the effective lever of the "instant center" (I. C. )

of the rear suspension links. The I. C. is the intersection of the imaginary

projection of the link pivot points, and is illustrated below for a 1968-72

GTO at normal chassis height both stock and equipped with various popular

traction aids. Except for the JR Coil Spring Bar, as the chassis lifts, the I.

C. moves towards the front of the car. The further the I. C. from the rear, the

less chassis lift. The amount of movement of the instant center depends on the

particular geometry.

INSTANT CENTER

Stock

- At stock chassis height, the instant center is 42" forward of the axle

centerline. At maximum chassis squat, the closest the I. C. comes to the axle

is 23". At a little over 2 -1 /4" chassis rise from stock

(4" axle to snubber distance), the upper and lower control arms are

parallel, resulting in an instant center infinitely far from the axle

centerline (i.. e. , no chassis lift at all ! ) . Greater chassis lift yet results

in an I. C. behind the axle which acts to pull the chassis down, not up. This

is very detrimental to good drag racing traction, so if you like to drive your

GTO around town or at the strip with the rear end way up in the air, it is no

wonder the tires just sit there and spin when you get on it! As a side note,

the H-O Traction Kit replaces the stock control arms with boxed section

and reinforced arms to assure that the rear suspension geometry stays at its

theoretical location and is not affected by high rpm starts and power shifts.

Ansen Bar

- Ansen makes a

traction aid which replaces the lower control arm and moves the rear lower

pivot point down about 4". Stock upper control arms are used with this

bar. The resultant change in geometry moves the stock chassis height I. C. in

to 33" forward of the rear axle. At maximum squat (axle to snubber

distance equal to zero), the I. C. is 23" from the rear axle. At full

extension (stock shocks with no shock extensions), the I. C. is 61 -1/2"

forward. At no time do the upper and lower control arms become parallel, so

some chassis lift is always provided.

No-Hop Bar

- Genuine Suspension, Mr. Gasket, Cal Custom, etc., markets a traction aid

which raises the upper rear pivot point. At stock height, this moves the I. C.

to 15" in front of the rear axle. At maximum squat it is 11-1 /2"

forward. At full extension, it is only 39" forward. This device provides

better chassis lift than the stock set-up or the Ansen Bar, but the amount of

the lift force varies significantly as the chassis rises.

JR Coil Springy Bar

- the JR traction bar effectively negates the lower rear pivot point and causes

the link-coil suspension to act like a leaf-spring rear suspension equipped

with "Action Bars. " The upper and lower control arms are retained

and the Coil Spring Bar is pure Bolt on, but the I. C. remains at approximately

the front lower pivot point distance of 21 1/2". This does not vary

significantly regardless of chassis rise which provides a constant chassis lift

force. Provision is also made for a "jacked up" rear suspension, so

that the action of the bar is not affected.

The following graph

illustrates the relative effectiveness of the above traction aids.

Compensation must also be made for the difference between driveshaft torque which tries to lift the rear tire and engine torque which tries to push the right rear of the chassis down. The most effective method is to use one air lift bag in the right rear coil spring. The inflation pressure increases both the static spring force and the spring rate. The correct inflation pressure depends on track conditions, engine torque, gear ratio, tire size and traction, etc. , but 12 -15 psi is a good starting point.